Part 1: What is a Control Chart?

A control chart, usually referred to and perceived as the Shewhart chart, a statistical control chart, or an SPC chart is a few graphical apparatuses commonly utilized in quality control examination to see how an interaction changes after some time.

The fundamental components of a control chart include:

- A visual time arrangement graph that shows information focuses gathered at exact time stretches.

- An even control line to all the more effectively picture variations and patterns.

- Level horizontal lines, addressing upper and lower control limits, put at equivalent distances above and underneath the control line. These upper and lower limits are determined from the information recorded on the time arrangement graph throughout a predetermined time frame.

Part 2: Purpose and benefit

There are many benefits of using a Control chart that will help you immensely in many ways. Those areas as following;

- Comprehend the variations that are consistently present in measures. Variations inside your control limits show that the cycle is working. Variations that spike outside of your control limits show issues that should be rectified.

- See when something is turning out badly or may turn out badly. These complex markers let you realize that restorative moves should be made.

- Notice designs inside plotted focuses. The examples show potential causes, which can help you discover possible arrangements.

- With a control chart, you can also anticipate future execution.

- It also allows you to create unique thoughts for improving quality dependent on your examination.

Part 3: Different types of process variation

If you are thinking of creating a control chart, you need to know process variations and their type before making a control chart. There is a whole process through which you can easily monitor and check if your strategy is stable or unstable. There are different types of variations for some special causes and common causes.

1: Common cause variations

The first type of variation process is the Common cause variations that are unique, unsurprising and consistently present in your cycles and can come under the variations for common causes.

The perfect example of the common cause variations can be the traffic. Consider how long it requires you to drive to work each day. You may go to a similar course each day, yet the drive is rarely something very similar. Maybe it takes you a usual short way from the time you take off from your home until you manoeuvre into the parking garage. Because of basic cause variations, for example, construction work, stop lights, some natural cause or gridlock—occasionally it will take less time, and different days it will require some investment.

Even though you don't know precisely when you will work tomorrow, you realize that it will fall within a satisfactory period, and you will show up on schedule. When variations stay inside your upper and lower limits, there is no pressing need to change your interaction because everything works inside unsurprising boundaries.

2: Special cause variations

In this type of variation, the causes are generally irregular and unusual. For instance, running on empty, motor disappointment, or a punctured tire could expand your drive by an hour or more, yet these sorts of unique causes won't occur each day.

At the point when particular cause variations happen, it's as yet a smart thought to break down what turned out badly to check whether these oddities can be forestalled later on. In our driving model, you could ensure you stop at a service station when you're coming up short on gas and ensure your vehicle is all around kept up to guarantee appropriate activity.

Part 4: What to do before creating a Control Chart?

There are steps that you need to take even before creating a control chart. Following is the list of things you need to do before you start your control chart.

- Pick the fitting control chart for your information.

- Write all the information you need to add to the paper’s control chart to not miss out on important information.

- Decide the reasonable period for gathering and plotting information.

- Gather information, develop your chart and examine the report.

- Search for "crazy signs" on the control chart. When distinguished, mark it on the chart and explore the cause: archive how you researched, what you realized, the cause and how it was adjusted.

Part 5: How to make Control Chart

These charts are the ideal chart to use in any way because they recognize common cause variety from particular cause variation. Follow these simple steps and make one for yourself.

Step 1: Choose the period because it is crucial to gather the information and build control limits.

Step 2: Gather all the essential information you need and begin plotting. Presently, from your data, ascertain the normal. Additionally, add a control line to your chart.

Step 3: After the control line, remember to calculate both the upper limits and the lower limits. Make sure to colour these lines differently in your chart and export them to your computer.

EdrawMax

All-in-One Diagram Software

- Superior file compatibility: Import and export drawings to various file formats, such as Visio

- Cross-platform supported (Windows, Mac, Linux, Web, Android, iOS)

Part 6: Tip for making Control Chart

- Recognize quality attributes of items or cycles that influence "qualification for use.” Keeping up control charts is a costly movement.

- Control charts ought to be kept up just for essential quality attributes. Plan of Experiments is one of the great sources to track down the critical quality attributes of the cycle.

- Plan the inspecting design and choose the technique for its estimation. We select the number of units in an example and how much time the administrator will take the measures at this progression.

- Make samples at various stretches and plot insights of the example estimations on a control chart.

Part 7: Example

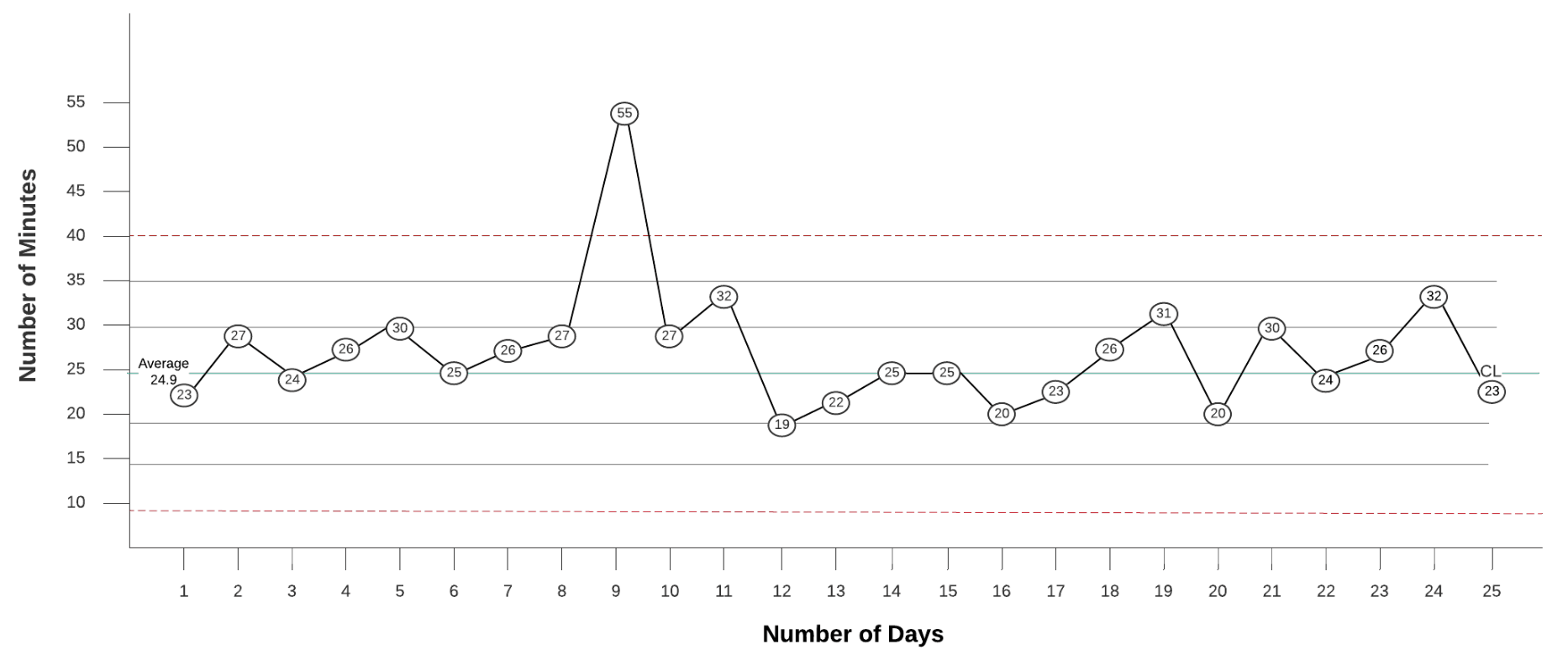

Suppose you need to record the measure of time it takes to drive to work each day for a set number of days. Consistently measure the extent of time it takes from the second you take off from your home until you manoeuvre into the parking area. After the information is plotted on a control chart, you can compute the average time it takes to finish the drive.

Source: cloudfront.net

In our chart above, the provided information was gathered for 25 sequential days. The determined normal demonstrates that it requires 24.9 minutes on average to make the outing every day. This usually turns into your control line, which appeared in green.