A Beginner's Guide for Kaizen Methodology

Edraw Content Team

Here we take a look at Kaizen methodology, how it works, its benefits, main elements, and principles and how one can implement the same in personal or work life. Kaizen instances of implementation in business organizations can be easily showcased by Edraw templates and charts.

What is Kaizen?

Kaizen is a Japanese quality control tool or process that imbibes the concept of continuous improvement. It is a Japanese word that means continuous improvement and it is a philosophy that strives to do good by continuous improvement. This Japanese continuous improvement philosophy is all about focusing on frequent and small changes in work processes that exist in an organization and bringing in the involvement of employees at different levels. The Kaizen methodology can be used on different functions in a business, from marketing, warehousing, finance, and others.

It acts as an approach that is simultaneous to continuous business process changes. These can be micro changes and help organizations build on improvements to see profitability and process changes that help in the steady and slow growth of an organization.

Image Source: gstatic.com

History of Kaizen

Kaizen was coined as a concept and term by Masaaki Imai when he wrote a book on it as being the key to competitive success in Japan. It was published in the fifties and Toyota implemented the method to showcase continual improvement in its technology, quality, and productivity and in measures of safety.

What are the Key Elements of Kaizen?

The key elements of Japanese continuous improvement or Kaizen are mainly five. These are known as founding elements such as:

- Personal discipline.

- Teamwork.

- Quality circles.

- Improved morale.

- Improvement suggestions.

The Kaizen method is a concept of Japanese management that stands for incremental that is gradual and continuous change or improvement. It is also a philosophy for way of life where one can incorporate the same principles when certain aspects of someone’s life need to be improved upon. Key elements of Kaizen 5s in corporate scenario include effort, quality, communication, willingness to bring about change and involving employees at different levels.

What are the Main Principles of Kaizen?

Main principles of Kaizen 5s are ten specific ones that are founded based on the qualities and key elements of Kaizen process. The ten principles based on this methodology are:

- Total quality control or six sigma

- Robotics

- Quality circles

- Customer orientation

- Automations

- Suggested systems

- Workplace discipline

- Total productive maintenance or TPM

- Quality implement

- Kanban

- Just in time or JIT

- Small group activities

- Zero defects

- Cooperative labor or management relations

- Productivity improvement

- New product development

How to Implement Kaizen Methodology?

When it comes to Kaizen methodology there are certain steps to take in order to implement the same in an organization. The main aim is to get employees to look at the present condition that is now and the desired state that they want to take their workplace or work processes to. Once they visualize the same they need to realize or brainstorm on the ways they can reach the desired state.

Image Source: nvision.co

Broadly, implementation takes place in three stages:

1. Encouraging Participation

Kaizen 5s, its key elements and principles need to start with awareness training. Implementers in an organization need to encourage employees to get involved and promote certain Kaizen activities. They need to think of the tangible or monetary benefits that would result from implementing certain Kaizen activities.

2. Education and Training

The essence of Kaizen method needs to be discussed and elaborated to employees and associates. Focused training is required for the same. Team leaders need to be trained in what the Japanese continuous improvement process methodology is all about and how the same can be implemented in the context of their organization’s vision and context; they need to be taught on how to conduct impartial evaluation as well as come up with strategies to improve participation.

3. Improvement of Quality Levels

Once training stage is done, practitioners can then focus on how to implement it in the long term and come up with widespread application of Kaizen 5s. It helps to align organizational objectives with what is planned and it is often ideal that a core department is assigned to evaluate and carry out Kaizen implementation.

4. How to Use Kaizen in Personal Life?

Kaizen as an approach can be used in one’s personal life to bring about desired changes or improvements. The different elements or principles that it imbibes can help one to gain insights into a particular problem. One can ask why a multiple times and get to an issue’s main root. For instance, if one wishes to lose weight, it could be linked to questions such as why one wishes to lose weight and how that can help them. If it seems silly to simply look good, one could also look at other linked reasons such as feeling good and staying healthy. It also gives more energy with which one can accomplish several tasks.

Weight loss is one of the Kaizen examples that one can utilize in bringing about a change in their personal life or to continually improve upon the same.

5. How to Use Kaizen to Improve Business?

If one wishes to establish Kaizen in their workplace, one of the Kaizen examples for organizations could be to bring about a change in company culture. Employees could be informed that things would be done differently. Clear suggestions would be encouraged so that process improvements can be made and employees on the other hand would be valued as well as rewarded.

In order to implement Kaizen in one’s organization successfully, management team need to be trained and made to walk the talk. If any suggestion or help is offered for improvement, then these should be considered. An organization could also establish a process whereby suggestions made by employees are accepted, their feasibility are considered and plan of action taken up. This can be done in three stages:

- All suggestions submitted are considered and then evaluated; if not practicable employees are provided the feedback accordingly.

- Employees are trained on process improvement and how they can contribute towards it.

- A rewards system is created whereby employees who work hard and showcase process improvement are rewarded of the same.

Image Source: tallyfy.com

EdrawMax

All-in-One Diagram Software

- Superior file compatibility: Import and export drawings to various file formats, such as Visio

- Cross-platform supported (Windows, Mac, Linux, Web)

Choose an Edraw Template to Fit your Needs

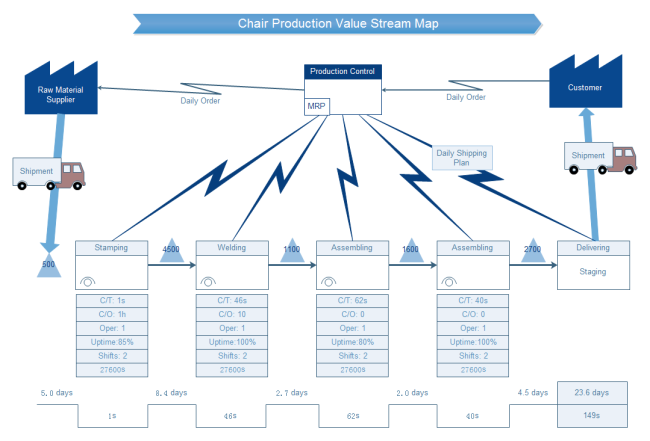

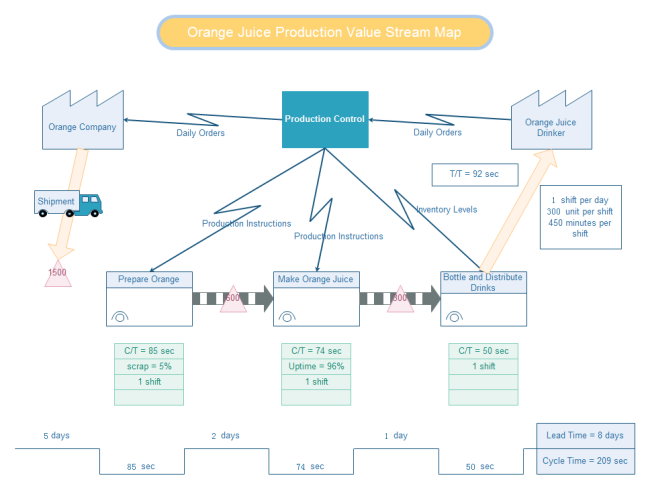

EdrawMax has different templates that can help draw up plans for process improvement. For instance, value stream mapping is a technique which is used by several firms to define and then analyze as well as optimize material or information flow for a production process.

In such a model there are steps where values are added and steps which are non-value adding. These help managers or teams to build a system of information flow as well as plan a more integrated and efficient use of resources.

PDCA or plan-do-check-act is another handy way to showcase Kaizen process implementation. There are handy templates available on Edraw.

A handy tool for bringing about continual improvement or initiating changes is Kaizen. Its key elements and principles provide several ways for one to implement it in personal lives or in company procedures.