What is an Industrial Control System

What are Industrial Control Systems?

Industrial control systems describe a set of control systems where the devices, networks and controls are used to automate and/or operate industrial processes. Different types of industrial control systems include Supervisory Control and Data Acquisition (SCADA), Distributed Control Systems (DCS), and Programmable Logic Controllers (PLC).

Industrial control systems allow for different manufacturers to exchange information seamlessly. It can also lead to an increase in performance, reliability and safety of the systems.

History of Industrial Control Systems

Industrial control systems evaluated from simple water clocks to sophisticated digitally controlled systems in centuries. If we want to see the evaluation in highlights, here is the briefest account.

1. We found records of automated machines from ancient times. Even in 250 B.C, there was a control device in the form of a water clock. One of the initial feedback control devices was developed in Egypt around 250 B.C. in a water clock.

2. In 1620, Cornelis Drebbel designed the first thermostat to operate a system. Later, in the 1700s, an incubator temperature came up as a closed-loop control system. This system provided feedback to the liquid and controlled the temperature.

3. Then the famous steam engine came into being in 1788.

4. In 1873, Jean-Joseph Léon Farcot published his book to introduce servomotors, again a form of Industrial control system.

5. The 20 years between 1900 and 1920 were the most revolutionary years for control systems. All the relay logic makes the foundation for computational and electrical devices.

6. Then came ship stabilization, autopilot techniques, and ‘Negative Feedback’ was developed around the first 30 years of the 1900s.

7. Digital control systems were out in the market around 1959, and the rest is history. We now have a sophisticated version of the Industrial control system(ICS).

8. And we do not see the end of evaluation here. It is changing day after day to become robust, easy to use, and more efficient.

Types of Industrial Control Systems

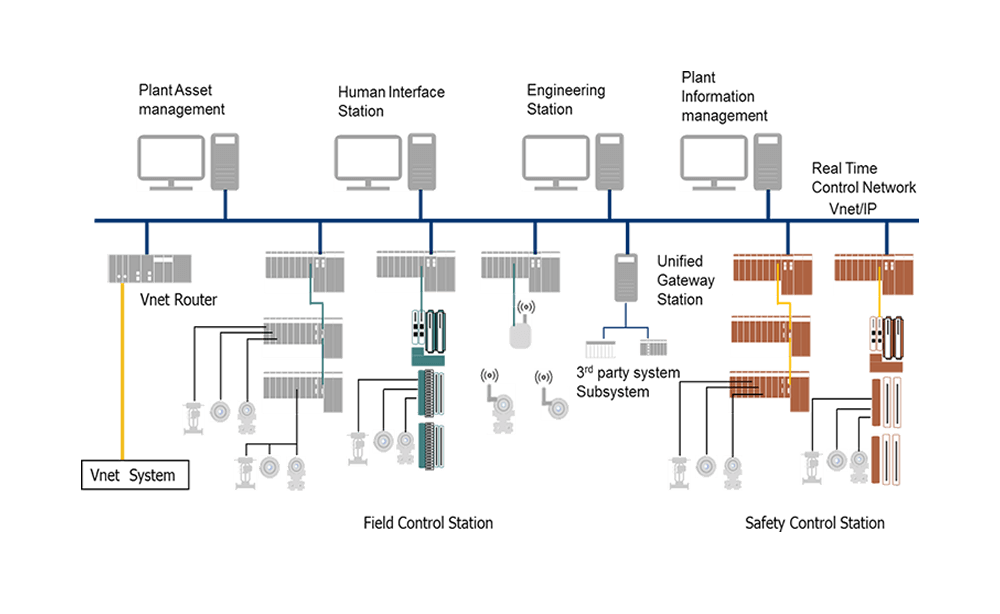

1.Distributed Control Systems (DCS)

This industrial control system is deployed and controlled in a distributed manner. So, various control systems and processes are controlled individually rather than by a centrally located single unit.

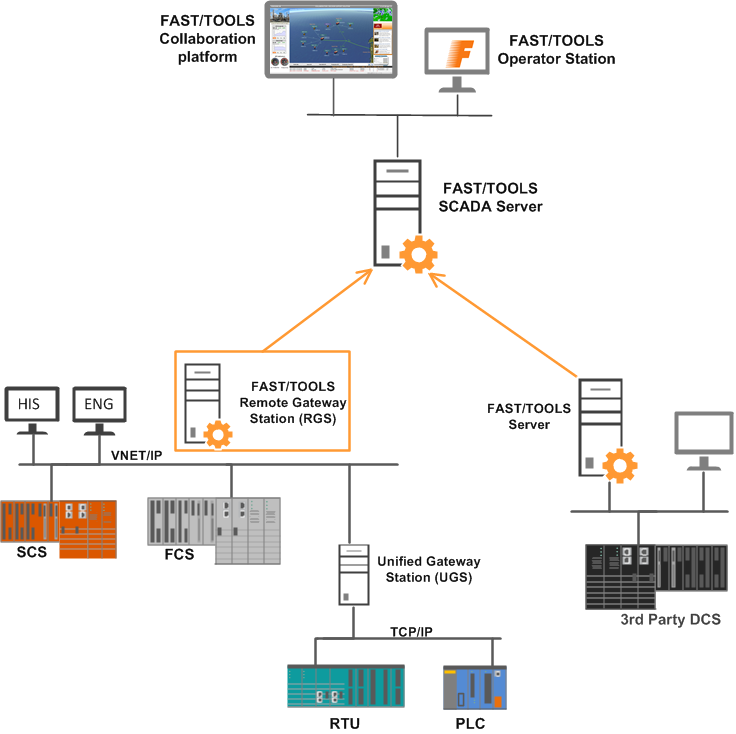

2.Supervisory Control and Data Acquisition (SCADA)

This is a computerized system that can gather and process data and apply operational controls. This can be done over long distances. SCADA is aimed at minimizing the communication challenges like delays and data integrity). SCADAs are used in power transmission and distribution, and pipeline systems. Usually shared rather than dedicated.

3.Hybrid

The actual implementations of ICS are usually a hybrid of both Distributed control systems and supervisory control and data acquisition (SCADA).

4.Industrial Automation and Control Systems (IACS)

These control systems use sensors on machines, smart devices, and infrastructures for communication. Industrial automation control systems are a combination of hardware, software, and communication alternatives to achieve the transformation of sensor information into information

Use case: Industrial Control Systems used in what fields or areas

Industrial control systems have widespread applications in many industries ranging from the small scale to the largest possible process system. Here we are discussing only two use cases to explain what an ICS can do briefly.

1. Quality Monitoring in paper and pulp industries

A comprehensive quality monitoring and control system covers the entire pulp and paper production line and beyond. It covers every aspect of the product life cycle, from measurements, controls, and profilers, to condition monitoring and machine vision, into one scalable system. It may consist of all the devices and applications one needs to monitor and optimize process performance and end-product quality.

2. Cybersecurity

This industrial control system is used to combat cybersecurity risk and operational disruption for industrial organizations. It does so by protecting the use of removable media including USBs, and thumb drives, against cyber risk and unauthorized usage. Through this system, operators get control and visibility.

EdrawMax

All-in-One Diagram Software

- Superior file compatibility: Import and export drawings to various file formats, such as Visio

- Cross-platform supported (Windows, Mac, Linux, Web, Android, iOS)

Industrial Control System Examples

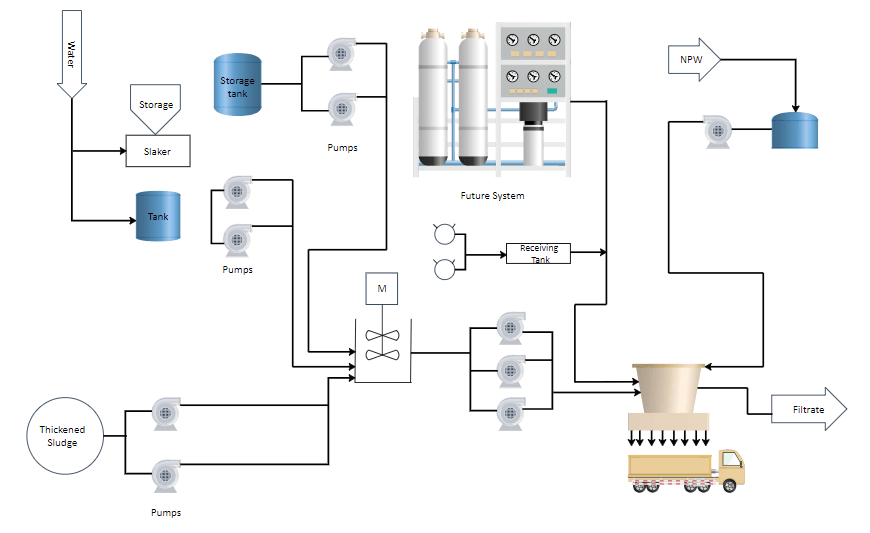

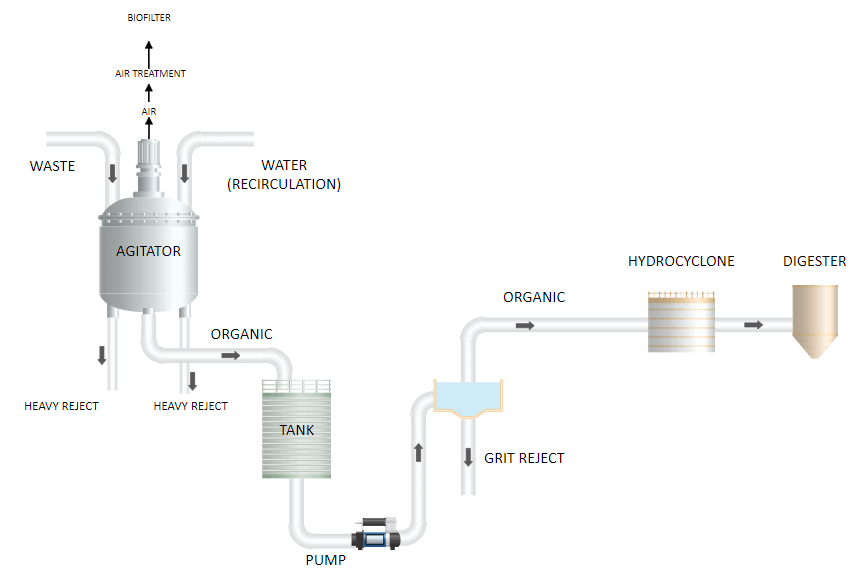

Example1: Wastewater Treatment Plant

This diagram shows the physical layout of a wastewater treatment plant. Wastewater is any water that requires cleaning after it is used. The goal of wastewater management is to clean and protect water。

Example2: Biogas Production System

Biogas is the mixture of gases produced by the breakdown of organic matter in the absence of oxygen, primarily consisting of methane and carbon dioxide. Biogas can be produced from raw materials such as agricultural waste, manure, municipal waste, plant material, sewage, green waste or food waste.

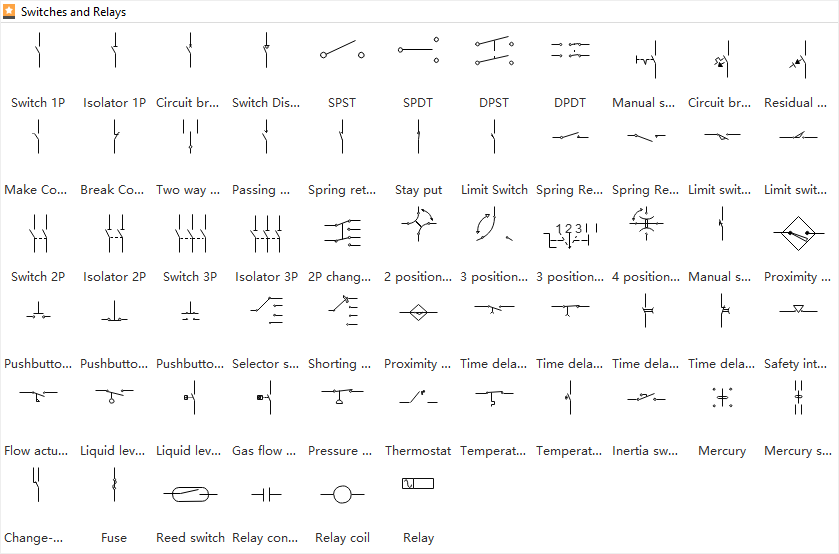

Create a system diagrams easily with the help of symbols and templates. The associated templates include a wide range of electrical and electronic elements.

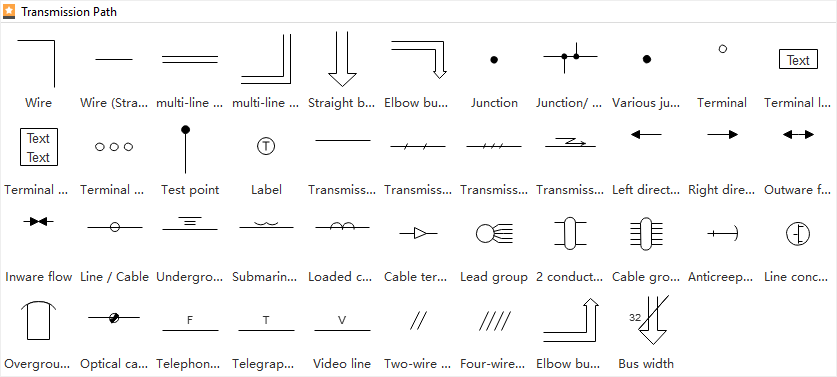

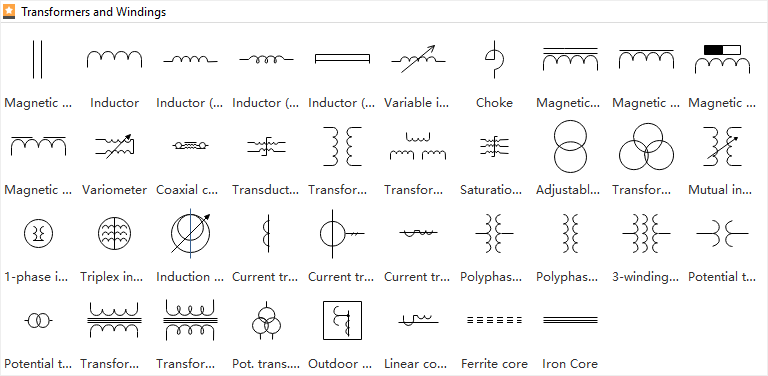

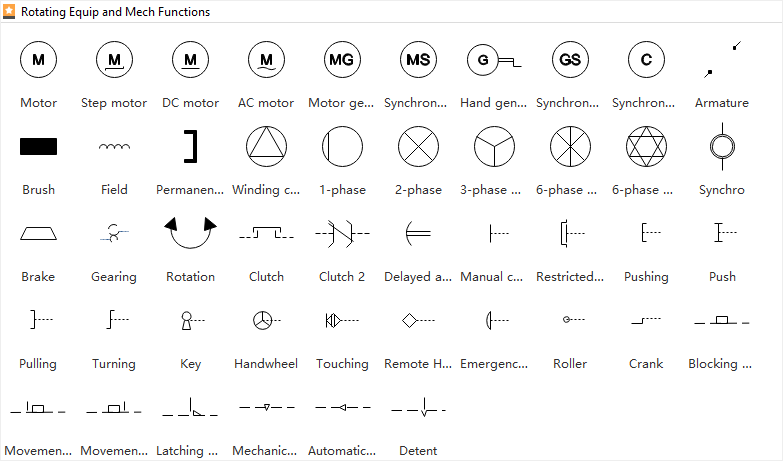

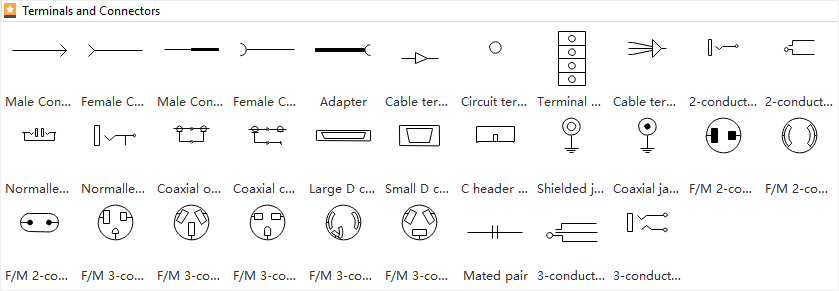

For example, the Fundamental Items stencil includes electronic items such as resistors, capacitors, and inductors. The Rotating Equip and Mech Functions stencil includes complete motors and motor components such as fields. You'll also find stencils that include shapes for switches, relays, terminals, connectors, transformers, windings and transmission paths.

Transmission Path

Transformers and Windings

Rotating Equip and Mech Functions

Terminals and Connectors

Switches and Relays

More Related

How to draw electrical engineering diagram